Integrated Extraction System

Leaders in taste technology

Flavourtech’s Integrated Extraction System (IES) is a continuous, automated processing line that allows customers to produce premium aromas, extracts and concentrates for the Ready-to-Drink (RTD) coffee and tea market, the instant coffee industry and for the fragrance and flavour industry. Built as a modular system, the IES can be inserted into existing process lines as required to make gradual improvements, or installed in its entirety to form a continuous process line, allowing aroma recovery, extraction and concentration in one simple-to-operate system.

As a semi or fully automated system, an IES process line can be operated with minimal staff. The easy-to-clean design allows different products to be processed with minimal downtime between runs. Quality is assured, as the modules are programmed for consistent results from run to run.

IES modules available include:

- Slurry Preparation module

- Flavour Extraction module

- High temperature extraction module (for instant coffee production)

- Solids separation module

- Clarification module

- Filtration module

- Wash module

- Concentration module

The IES is Flavourtech’s solution for those looking to deliver market leading RTD tea and coffee products to discerning consumers around the world.

How it works

An IES250 complete processing line

The IES couples innovative flavour extraction techniques with effective soluble solids extraction. The flavour is captured as part of the brewing process and then stored separately to avoid damage or deterioration. A short residence time, low temperature evaporator is used to concentrate the extract ensuring minimal thermal damage and colour changes. Finally, the captured flavour is added back to the concentrated extract to produce the world’s finest coffee, tea and other botanical concentrates.

The IES modules are:

Slurry Preparation module

This module accepts tea leaves, roasted coffee beans, or other plant material and employs specialised milling techniques to minimise flavour loss. Water is mixed with the milled material to form a slurry. The slurry is then fed into the Flavour Extraction module.

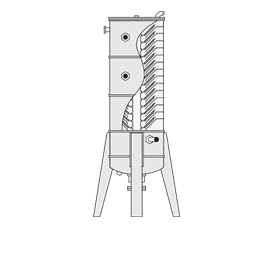

Flavour Extraction module

IES25 pilot plant facility

Integral to the system is the Flavour Extraction module or Spinning Cone Column system (SCC). The SCC collects the volatile flavour compounds as soon as they are released. The extracted flavour is heavily weighted in light, ‘front-end’ compounds, which are generally lost in other extraction techniques. The flavour is stored, avoiding potential damage of subsequent processing, to be added back to the concentrated extract at a later stage. For tea and coffee processing the SCC performs the dual role of flavour and soluble solids extraction, that is, brewing the tea and coffee at the same time as recovering the aroma.

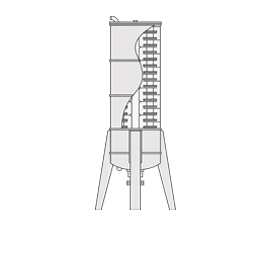

High Temperature Extraction module (used for soluble coffee)

High temperature extraction is carried out using Flavourtech’s Rotating Disc Column system (RDC). The RDC is a continuous extraction column that allows temperatures of up to 200°C to be used for soluble solids extraction in the coffee process. Once the desired aroma has been captured and protected, the slurry leaving the SCC flavour extaction module goes directly to the RDC. RDC residence time is typically only 20 minutes and requires a single pass to achieve similar yields to what conventional extraction systems need more than two hours to achieve.

Clarification module

The flavour-stripped slurry exiting the Flavour Extraction module is a mixture of extract and insoluble solids. The Clarification module may consist of one or more systems to meet the clarity requirements of the customer’s final product. As a first step it involves the removal of bulk solids followed by either removal of fine particulates or a polishing stage to obtain extracts often described as “bright” for packaging in clear PET bottles.

Wash module

The wash module increases the yield of soluble solids recovered from the coffee bean or tea leaf.

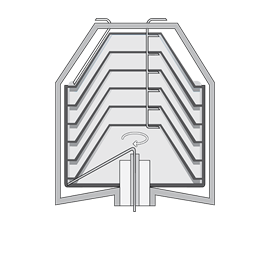

Concentration module

The concentration module consists of the Centritherm® evaporator: a centrifugal evaporator with extremely short residence time (around one second). High concentration ratios can be achieved in a single pass without thermal degradation of flavour, colour or active ingredients.