Rotating Disc Column

Innovation in taste technology

The Flavourtech Rotating Disc Column (RDC) is a continuous contacting device for the food and beverage industries. It can be used where well-defined contact times are necessary for the soluble components to be efficiently transferred from within solid particles to a liquid medium.

The RDC allows temperature, pressure and residence time to be controlled precisely to obtain near identical conditions for all parts of the mixture being processed, ensuring consistency in processing and ultimately, contributing to a superior end product.

In contrast to batch tank processing, the RDC’s continuous and automated process means labour, energy and overall production costs are reduced as time is not spent filling and emptying tanks.

Applications of the RDC include:

- High temperature extraction of soluble solids from slurries in the instant coffee industry following the aroma recovery process

- Continuous reaction processes in the food industry where precise temperature and times are required, for example enzymatic reactions

- Continuous mixing of liquid/solid mixtures in the food and beverage industry for obtaining a consistently mixed product prior to feeding to the next step in the process line

How it works

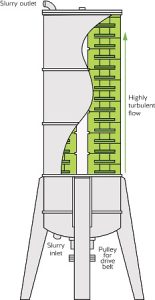

The RDC is a continuous extraction device operating in plug flow. Its function is to hold a slurry flow (of solids in liquid) for a specified residence time and at a specified temperature so that the transfer of soluble components from the solid particles to the liquid extract is maximised.

The RDC is a continuous extraction device operating in plug flow. Its function is to hold a slurry flow (of solids in liquid) for a specified residence time and at a specified temperature so that the transfer of soluble components from the solid particles to the liquid extract is maximised.

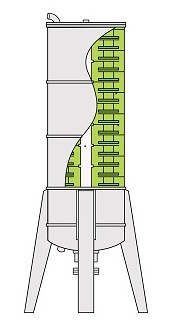

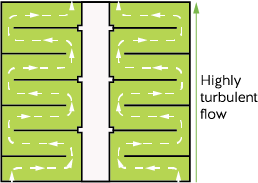

Inside the RDC is a central, vertical drive shaft. Attached to the shaft is a series of rotating discs; between each adjacent pair of rotating discs is a stationary disc, fixed to the column, which has a hole at its centre. Slurry moves up the column following the general path indicated in Figure 1. Rotation is used to keep the solids in suspension; wiping/stirring blades (not shown) attached to the discs assist this function.

Figure 1: Product flow through the RDC

The residence time (that is, the time any portion of the slurry spends in the RDC) is typically in the range of 20-30 minutes. The internal volume of the RDC is determined by the desired product flow rate and holding time and is tailored to customer requirements.