Spinning Cone Column

Better flavours, better aromas – Naturally

Our flagship product – the Spinning Cone Column (SCC) – is designed to extract and recover volatile compounds using steam, under vacuum conditions. This is a far more gentle process compared to standard extraction techniques, enabling our equipment to better capture aromas and flavours – naturally.

Used across multiple industries, applications for the SCC include:

- Aroma recovery during instant coffee production

- Simultaneous flavour and soluble solids extraction from coffee and tea slurries for the production of ready-to-drink (RTD) beverages

- Dealcoholisation and alcohol management in wine, beer and other alcoholic beverages

- Deodorisation of cream and flavour management of dairy products

- Aroma recovery and preservation during production of fruit and vegetable purees and juices

- De-oiling of NFC (Not From Concentrate) citrus juices

- Essential oil extraction from botanicals, herbs and spices

- Extraction of pure flavours from fresh fruits

The SCC has been proven to deliver significant returns on investment through the recovery of superior flavours, aromas and extracts by maintaining the natural characteristics of the raw material. Equipped with state of the art control and automation, and built using 316 grade stainless steel for all product contact surfaces, the SCC operates as a continuous processing system delivering superb operational efficiency and maximising factory uptime.

How it works

Figure 1

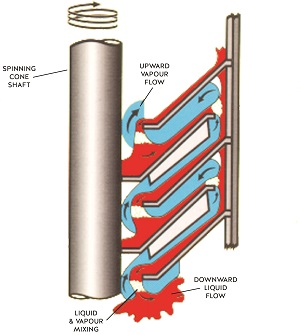

The Flavourtech Spinning Cone Column is a stripping column in which steam separates volatile compounds from liquids or slurries under vacuum.

The column itself is a vertical, stainless-steel vessel with a central rotating shaft. It contains a series of alternate rotating and stationary cones, the rotating cones attached to the shaft, the stationary cones fixed to the wall of the column. A cut-away diagram of a single cone set is shown in Figure 2.

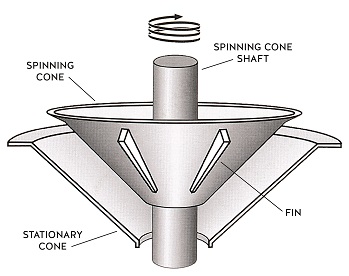

Figure 2

The feed material, from which the volatile compounds are to be separated, is fed into the top of the column. This material, either liquid or slurry, flows as a thin film (approximately 1mm film thickness) down the upper surface of the first stationary cone. It then drains through the outlet of the stationary cone on to the base of the spinning cone immediately below. Centrifugal force, generated by the rotation of the cone, causes the liquid to flow upwards and outwards across the upper surface of the spinning cone, again as a thin film.

This film breaks up as it moves from the lip of the spinning cone; the liquid is then guided downwards on to the next stationary cone, and the cycle is repeated. In this manner, the liquid works its way, cone by cone, from top to bottom of the column.

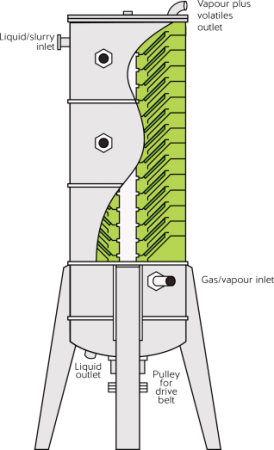

Figure 3

At the same time as liquid is flowing down the column, stripping steam (vapour) is introduced into the base of the column. The vapour flows upwards, across the surfaces of the volatile-rich liquid films, separating (or stripping) the volatile compounds from the liquid. Fins on the undersides of the rotating cones promote turbulence in the vapour stream, increasing mass transfer efficiencies. Figure 3 illustrates the flow of liquid and vapour through the column.

The temperature and flow rate of the stripping steam can be controlled. The ability to control these parameters allows different aroma profiles to be captured from the same raw material to produce different aromas for multiple markets or products.

The vapour, which is now steam mixed with the volatiles stripped from the product, flows out of the top of the column and passes through a condensing system which captures the volatiles in a concentrated liquid form. The remaining liquid or slurry is pumped out of the bottom of the column.