System Process Lines

Quality products, consistently

Over the years Flavourtech has accumulated a wide range of experience that allows us to provide both automated and semi-automated process lines that produce more consistent, higher quality products with less effort. In addition to reducing labour costs, Flavourtech’s compact lines mean a smaller operational footprint and reduced downtime through the automation of product or batch changes.

Here’s a snapshot of some of our recent projects:

- Extraction line for ready to drink (RTD) tea and coffee

- Meat broth extraction and concentration process line

- Plant extraction and concentration process line

How it works

These System Process Lines are designed to meet each customer’s specific objectives. Another example is outlined here.

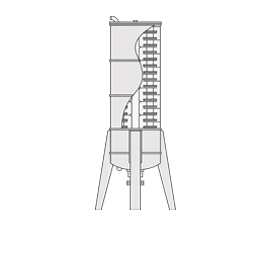

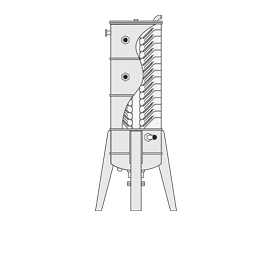

Flavourtech’s expertise came to the rescue of a meat bone broth extraction company by helping them to meet product specifications they were not previously able to achieve.

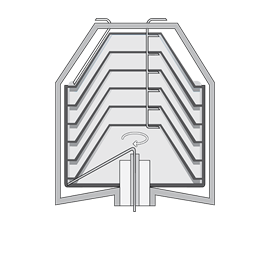

Flavourtech designed a series of batch kettles that operated automatically and allowed the broth to be fed directly to the Centritherm evaporator. This meat bone broth production line produced a consistent quality, lighter coloured extract at a reliably higher concentration than their previous extraction lines. This allowed the broth company to meet the requirements of existing and new customers and grow their business three-fold in a very short period of time.